Calculate your inventory-to-sales ratio to balance between those and learn how this ratio affects your inventory management also what is a good inventory-to-sales ratio and how to maintain it. This ratio can help to forecast your inventory level also you can reduce your inventory tax by holding an optimum level of inventory.

What is the inventory-to-sales ratio?

The inventory-to-sales ratio measures the relationship between a company’s inventory and its sales over time. It is calculated by dividing the average inventory value by the net sales value.

The inventory-to-sales ratio is an important metric in inventory management, it helps companies in how they assessing their inventory efficiently relative to their sales.

This ratio helps businesses understand their inventory levels relative to their sales and can be used to evaluate whether they need to adjust inventory purchasing, production levels, or sales strategies. Regularly monitoring this ratio can help companies make informed decisions on inventory management, optimizing their overall operational efficiency and profitability.

What Does the Ratio Mean?

- High Ratio: A high ratio can suggest that a company is holding too much inventory compared to its sales. This may lead to increased holding costs, risk of obsolescence, or tied-up capital that could otherwise be used more productively.

- Low Ratio: A low ratio may indicate that the company is efficiently converting its inventory into sales, which can be a positive sign of demand for its products. However, an excessively low ratio could also imply that the company may run the risk of stockouts, which could lead to lost sales.

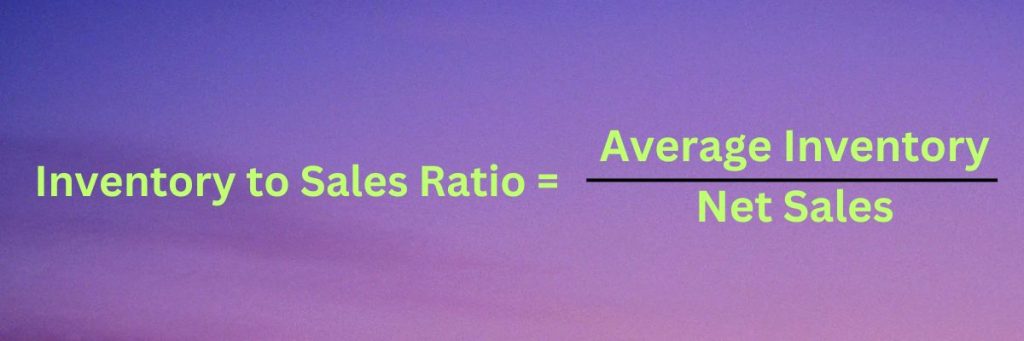

Inventory-to-sales ratio formula

You can calculate the inventory-to-sales ratio by dividing the average inventory value by the net sales. Average inventory is the value of inventory that your business holds during a certain period. Sales can be defined as the total value of sales after deducting the sales return.

What is a good inventory-to-sales ratio?

A “good” inventory-to-sales ratio depends on the industry, business model, and operational strategy of a company. However, here are some general guidelines to help determine what might be a favorable ratio:

Industry Standards: Inventory to sales ratio by Industry

- Retail and Consumer Goods: Typically, a lower inventory-to-sales ratio (1:1.0 to 2.0) is preferred in these industries, as they rely on fast inventory turnover to meet customer demand and minimize holding costs.

- Manufacturing: A slightly higher ratio (e.g.,1:2.0 to 4.0) might be acceptable, as manufacturers often need to maintain more inventory to support production schedules and account for longer lead times.

- Automotive and Heavy Equipment: These sectors often have higher ratios (e.g., 1:5.0 or more) due to the high value and slower turnover of inventory items.

- Technology and Electronics: Lower ratios (e.g., 1:1.5 to 3.0) are common because products often have shorter life cycles and businesses must avoid holding obsolete stock.

A low ratio is typically considered good in many industries, as it suggests that inventory is moving quickly and the company is generating strong sales. However, a meager ratio may indicate insufficient inventory, leading to stockouts and lost sales.

A high ratio could signal inefficiency, such as overstocking or slow-moving inventory, leading to higher carrying costs. This might be acceptable for industries with high-value, slow-moving goods.

Some Key Factors to Consider

- Seasonality: Some businesses experience seasonal fluctuations. A higher ratio may be acceptable before peak periods (e.g., retail before holidays).

- Business Model: E-commerce businesses may have lower ratios due to just-in-time inventory practices, while brick-and-mortar retailers may maintain higher ratios for in-store availability.

- Growth Stage: Startups or expanding businesses may have higher ratios as they build inventory to support growth.

- Efficiency Goals: The ratio should align with company goals for inventory turnover and customer service levels.

How to Optimize the Ratio

- Demand Forecasting: Use accurate sales forecasts to manage inventory levels.

- Just-in-Time (JIT): Adopt inventory management systems that reduce carrying costs while meeting demand.

- Inventory Control: Regularly review and optimize stock levels for slow-moving and fast-moving products.

- Technology Integration: Implement inventory management software to track and adjust inventory in real time.