Knowing inventory accuracy rate is important for any business to manage inventory properly and efficiently. This inventory accuracy calculator helps you to determine it with a click. And we’ll discuss more on how you can maintain a higher inventory accuracy rate also prevent inventory mismatch.

What is Inventory Accuracy Rate?

The Inventory Accuracy Rate is a metric used to measure the accuracy of recorded inventory data compared to the actual physical inventory on hand. It evaluates how well a company’s inventory records align with the physical stock, ensuring reliable inventory management.

A high accuracy rate indicates effective inventory tracking, which minimizes errors in stock levels, improves customer satisfaction, and reduces costs associated with overstocking or stockouts.

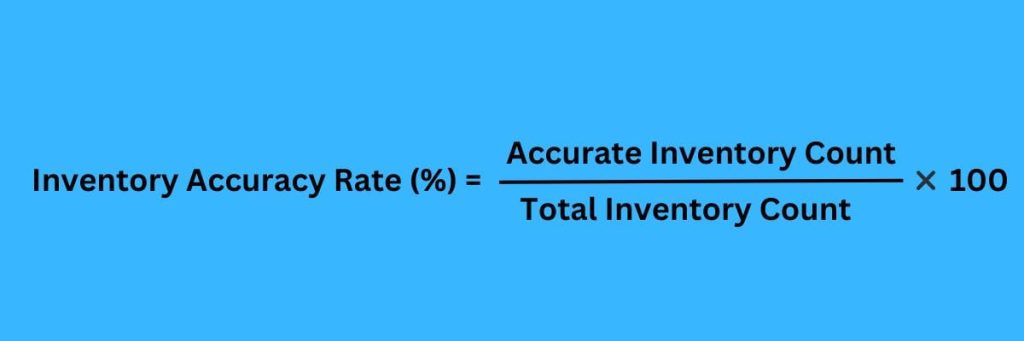

The formula to calculate inventory accuracy rate is:

Key Components:

Accurate Inventory Count: The number of manually counted items, where the recorded quantity matches the physical quantity.

Total Inventory Count: The total number of inventory items reviewed during a stock audit, or number of items recorded on books.

Example Calculation:

If a company has 1,000 total inventory items and 980 of them match the recorded quantity during a stock audit, the accuracy rate would be:

Inventory Accuracy Rate = (980/1000) × 100 = 98%

Here are Key Benefits of Maintaining a High Inventory Accuracy Rate:

Improved Customer Satisfaction: By maintaining a high inventory accuracy rate you can ensures customers receive what they order without delays.

Cost Savings: Reduces costs from overstocking, stockouts, or order errors.

Efficient Operations: Streamlines warehouse operations and avoids delays due to inventory discrepancies.

Better Decision-Making: Provides accurate data for demand forecasting, procurement, and inventory planning.

Fraud prevention: By calculating the inventory accuracy, you can prevent any fraudulent activities regarding to inventory management.

Key Strategies to Improve Inventory Accuracy:

Keeping inventory counts accurate and maintaining a higher inventory rate is essential for any businesses who works with physical product.

- Conduct regular cycle counts instead of annual counts.

- Use barcode scanning or RFID systems for precise inventory tracking.

- Implement robust inventory management software to reduce human errors.

- Establish clear inventory receiving and shipping processes.

- Do inventory audit frequently.

- Train staff on accurate inventory handling and recording practices.

Why Inventory Accuracy Rate Get Lower?

The inventory accuracy rate get lower for inventory mismatch. Here are the common reasons that may lead to a low inventory accuracy rate.

- Human Errors:

- Data Entry Mistakes: Incorrectly entering quantities, item codes, or other details into the inventory system.

- Counting Errors: Errors during stocktaking, such as miscounting or double-counting items.

- Mislabeling: Items placed in the wrong location or labeled incorrectly, leading to confusion during audits or picking.

- Poor Inventory Management Processes

- Lack of Standardized Procedures: Inconsistent methods for receiving, counting, or recording inventory.

- Failure to Update Records: Delays in updating inventory levels after sales, returns, or stock transfers.

- Improper Cycle Counting: Irregular or poorly conducted inventory counts can miss discrepancies.

- Theft and Shrinkage

- Internal theft: Any internal theft by employee or other staff members.

- Shoplifting: Customer theft in retail settings.

- Supplier Fraud: Receiving fewer goods than invoiced but recording the expected quantity.

- Damage or Loss

- Damaged Goods: Items that are damaged during transportation, storage, or handling but not recorded as unusable.

- Loss During Handling: Losses from accidents, such as spills, breakages, or misplacement.

- Obsolescence: Forgotten or expired stock not recorded as unavailable.